News

The Potential of 3D Printing in Boat Manufacturing

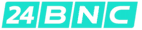

Companies in the Netherlands are investing in the use of 3D printing technology to manufacture hulls, with the expectation that it will lead to more affordable boat production.

A rigorous test was conducted, with Maarten Logtenberg using a sledgehammer to strike a sample of the new material. The results were impressive, as the hammer bounced off with minimal impact, leaving only a slight mark.

Following a two-year period of experimentation, a breakthrough was achieved in developing a unique blend of thermoplastics and fibreglass. This innovative material boasts exceptional strength, requires no additional coating for UV protection, and exhibits resistance to fouling and marine growth.

According to Mr Logtenberg, this material provides an ideal foundation for 3D printing a boat, offering a range of benefits that make it an attractive option for marine applications.

The marine environment is notoriously harsh, and boats must be designed to withstand its unforgiving conditions. This is one reason why traditional boatbuilding is often a labor-intensive and time-consuming process.

However, after months of fine-tuning the material's chemistry, CEAD was able to produce its first hull in just four days at its new factory. This marked a significant milestone in the company's efforts to revolutionize boatbuilding.

Mr Logtenberg notes that CEAD is automating nearly 90% of the boat-building process, significantly reducing production time. This streamlined approach enables the company to produce boats at a much faster rate than traditional methods.

Typically, building a hull takes several weeks. In contrast, CEAD can now print one every week, demonstrating the potential of 3D printing to transform the boatbuilding industry.

The story of CEAD's innovative approach to boatbuilding is one that 3D printing has long promised to deliver: a rapid, labor-saving production process that substantially reduces costs.

Although 3D printing has not always lived up to its promises, Mr Logtenberg is convinced that the maritime sector is an area where this technology can have a profound impact.

As co-founder of CEAD, a company specializing in the design and construction of large-format 3D printers, Mr Logtenberg has been at the forefront of this innovation. CEAD is based in the Dutch town of Delft.

Until now, CEAD's primary focus has been on providing 3D printers for other companies to use. However, with the advent of boatbuilding, the company has decided to expand its role and become involved in production as well.

Mr Logtenberg acknowledges that 3D printed boats still need to gain acceptance in the market. To address this, CEAD has taken a proactive approach, deciding to produce boats itself rather than simply providing the necessary equipment.

According to Mr Logtenberg, investors are often hesitant to commit to new technologies without a clear indication of market demand. By taking a hands-on approach to production, CEAD aims to demonstrate the viability of 3D printed boats and drive market growth.

Traditional fibreglass boatbuilding requires a mold and significant manual labor to ensure the vessel meets the required strength standards. In contrast, additive manufacturing streamlines this process by completing the necessary work at the design stage.

The design stage involves creating the software and printer, which can be a labor-intensive process. However, once this initial work is completed, the production phase can proceed with minimal human intervention.

3D printers operate by building up thin layers of material, following a predetermined digital design. This process enables the creation of complex objects with high precision.

As each layer is added, it bonds to the previous one, allowing for the formation of a single, seamless object. This approach enables the production of objects with intricate geometries and structures.

During the production phase, the primary requirement is a steady supply of the base material. With this in place, human intervention is minimal, and the production process can proceed autonomously.

One of the key benefits of additive manufacturing is the ability to make design adjustments without significant changes to the build process. This flexibility enables companies to respond quickly to changing market demands or customer requirements.

While 3D printing has made significant inroads in various industries, including dentistry, its application in boatbuilding poses unique challenges. Creating a vessel capable of withstanding real-world marine conditions requires a distinct approach.

CEAD's largest 3D printer, measuring nearly 40m in length, has been used to print an electric ferry for a customer in Abu Dhabi. This project demonstrates the company's ability to produce large, complex vessels using additive manufacturing.

Since establishing its Marine Application Centre in Delft, CEAD has made significant progress in boatbuilding. In the past 12 months, the company has produced a prototype 12m fast boat for the Dutch Navy, similar to a RIB.

Mr Logtenberg notes that traditionally, the Dutch Navy would have to wait years for a new boat, incurring significant costs. In contrast, CEAD was able to deliver the prototype in just six weeks, at a fraction of the cost.

Furthermore, CEAD can learn from the prototype and produce another vessel in the same timeframe, with the added benefit of being able to recycle the original boat. This approach enables rapid iteration and improvement.

Another area where 3D printing is gaining traction is in the production of unmanned vessels, such as nautical drones. CEAD recently participated in a test with Nato Special Forces, where drones were built on-site in a matter of hours, with designs adapting to operational requirements.

According to Mr Logtenberg, the flexibility of 3D printing is a major advantage. By relocating production closer to the end-user, companies can respond quickly to changing demands and reduce logistics costs.

Even large 3D printers can be transported in shipping containers, allowing for deployment in remote or hard-to-reach locations. This mobility enables companies to produce boats and other vessels in a variety of settings.

The size of the vessel is not a limiting factor, as the 3D printing process can accommodate a wide range of designs. As long as the base material is available, the machine can produce boats of varying sizes, from small work boats to larger military vessels.

The only logistical consideration is the transportation of the base material, which is highly efficient due to its compact packaging. In contrast, traditional boatbuilding often requires the transportation of large, finished vessels.

In the port city of Rotterdam, a company called Raw Idea, with its 'Tanaruz' brand, is exploring the potential of 3D printing in the leisure market, particularly in boat rentals.

Joyce Pont, Raw Idea's managing director, notes that while consumers may be hesitant to adopt 3D printed boats due to their novelty, the rental market is showing significant interest. The unique aspect of 3D printed boats can be a major marketing draw.

The use of social media platforms can help generate buzz around 3D printed boats, with customers eager to experience and share their encounters with these innovative vessels.

Raw Idea is also highlighting the eco-friendly aspect of its 3D printed boats, which are made from a combination of glass fiber and recycled consumer plastics, such as fizzy drink bottles.

Although the current cost of 3D printed boats is comparable to traditional vessels, the use of recycled materials increases production costs. However, as the technology scales up and becomes more efficient, costs are expected to decrease significantly.

Ms Pont is confident that within five years, 3D printed boats will dominate the market for fast-driving boats, such as work boats and speed boats, due to their improved performance and reduced production costs.

The marine industry is heavily regulated, and certification authorities are working to keep pace with the rapid innovation in 3D printing. Both Raw Idea and CEAD are engaging with European regulators to ensure compliance with existing standards.

As the industry continues to evolve, regulators must adapt to the unique characteristics of 3D printed boats, which often cannot be directly compared to traditional vessels.

The development of new materials and production methods is driving innovation in the marine sector, with companies like Raw Idea and CEAD at the forefront of this change.

While 3D printing has often been touted as a revolutionary technology, its impact has been uneven across different industries. Mr Logtenberg attributes this to the diverse range of applications and contexts in which 3D printing is used.

The varied nature of 3D printing applications can make it challenging to assess the technology's overall impact, as different industries and use cases may experience distinct benefits and challenges.

The field of additive manufacturing encompasses various applications, including metal printing, polymer printing, and large-scale printing, each with its own unique uses.

While some additive manufacturing applications have failed to gain traction due to competitiveness issues, others have successfully implemented the technology and are currently utilizing it.

Additive manufacturing is gaining traction in the shipping industry, albeit in specialized areas, rather than being used to construct entire ship hulls.

The potential of 3D printing in the maritime sector is still being explored, but the idea of printing entire ships in one process remains a distant goal.

Joyce Pont expresses doubts about the feasibility of automated shipbuilding in the near future, viewing the construction of luxury vessels like superyachts as a craft that will likely resist automation.

In contrast, Mr Logtenberg holds a more positive outlook on the future of additive manufacturing in shipbuilding.

Mr Logtenberg notes that he did not anticipate being able to build a 12-meter boat just a year ago, highlighting the rapid progress being made in the field.

Traditional shipbuilding involves a modular approach, and it may take around a decade or two for additive manufacturing to reach the point where entire ship hulls can be printed, pending further research into suitable materials.

As thermal plastics continue to be developed and improved, and machinery is scaled up, the possibilities for additive manufacturing in shipbuilding are expanding, raising the question of what can be achieved in the future.

News

GB men’s curling team suffers upset defeat to Italy

At the 2026 Winter Olympics, Great Britain’s men’s curling team mounted a comeback against Italy following a disappointing beginning, ultimately falling short in their inaugural match.

Despite a valiant comeback, Team GB ultimately fell short as Italy held their composure to secure the win in the final end.

A dismal start to the match proved costly for Team GB's men, as they suffered their first defeat of the Winter Olympics at the hands of host nation Italy, despite a spirited fightback in the packed Cortina Curling Stadium.

Following victories in their first two matches, including a win over the Swedish rink that beat them in the gold-medal match four years ago, Team GB entered their second high-profile encounter in as many days in a confident position.

However, a disastrous opening end, in which Italy stole four points, left Team GB trailing and facing an uphill battle in front of a boisterous home crowd.

The British team, currently ranked number one in the world, gradually regained their footing and managed to level the score by the ninth end.

Ultimately, Italy maintained their composure in the final end to emerge victorious, winning 9-7 and adding Team GB to their list of scalps, which already included the Swedes.

"We had to dig deep and play some solid curling, but unfortunately, it wasn't enough to get us over the line," Team GB lead Hammy McMillan said in an interview with BBC Sport.

With seven wins from nine round-robin matches guaranteeing a spot in the semi-finals, Team GB remains in a strong position, although fewer wins may still be sufficient to advance.

The women's team is set to take to the ice next, facing South Korea in their second match at 13:05 GMT, while the men will return to action on Saturday against the Czech Republic at the same time.

Team GB is at the forefront of curling's technological advancements.

Embracing what sets you apart can be a powerful asset, according to some athletes.

A daily guide to the Winter Olympics is available for those looking to stay up-to-date with the action.

The looks of shock on the faces of Team GB's curlers told the story of a disastrous opening end.

With a stone in play, Mouat attempted a risky shot in an effort to claim two points, but it backfired, resulting in none of Team GB's stones in the house and four Italian stones in position.

However, the Scottish quartet, ranked number one in the world, quickly regained their composure and got back to their game.

The teams exchanged singles before a impressive final throw by Mouat, aided by a measurement to determine which stone was closest to the button, allowed Team GB to claim two points and narrow the gap to 5-3.

Another excellent team effort, which included a well-judged throw by Mouat, a solid sweep by Hammy McMillan and Bobby Lammie, and Grant Hardie's strategic expertise, forced Italy to concede a point in the fourth end, reducing the deficit to a single point at the break.

Italy blanked the sixth end and added two points in the seventh to rebuild their lead, but Team GB fought back with two points of their own, remarkably levelling the score with one end remaining after a steal.

The match came down to the final end, but Italy held their nerve to secure the win, prompting a deafening roar from the crowd.

"It's an incredible experience, and we need to get used to it," McMillan added, describing the electric atmosphere as "surreal" and "cool," more akin to a football match than a typical curling crowd.

News

Scotland Kicks Off Nations League Against Slovenia

Uefa has released the schedule for the Nations League, with Scotland set to begin their campaign on 26 September with an away match against Slovenia.

Uefa has released the schedule for the Nations League, with Scotland's campaign set to begin on 26 September with an away match against Slovenia.

The team's six group stage games will be played within a three-month period, culminating in a match against Switzerland on 16 November.

The fixture list was announced following Thursday's draw, which placed Scotland in a group with Switzerland, Slovenia, and North Macedonia.

Having been relegated from League A after a play-off loss to Greece last year, Scotland will compete in the second tier of the Nations League this year.

In response to the draw, head coach Steve Clarke noted that the teams in the group appear to be evenly matched.

Clarke reflected on the team's past experience in the competition, stating that it has been beneficial for Scotland.

He emphasized the importance of the Nations League, citing its role in helping the team qualify for Euro 2020, and anticipated a challenging set of matches.

A key matchup in the Nations League will see Scotland face off against Switzerland.

The group stage will determine the teams' fates, with the winner earning promotion, the runner-up entering a play-off, the third-placed team facing a relegation play-off, and the fourth-placed team being relegated directly.

The upcoming group games will mark a reunion for Scotland and Switzerland, who previously drew 1-1 in Cologne at Euro 2024.

Scotland's last encounter with Slovenia was during the 2018 World Cup qualification campaign, when they won 1-0 at home and drew 2-2 away.

The team has not played North Macedonia since the 2014 World Cup qualifiers, when they drew 1-1 at home and won 2-1 away, with goals from Ikechi Anya and Shaun Maloney.

The schedule for Scotland's Nations League campaign begins on 26 September with a match against Slovenia.

The team will then host Switzerland on 29 September, followed by a trip to face North Macedonia on 3 October.

Scotland will then play Slovenia at home on 6 October, before hosting North Macedonia on 11 November.

The final group stage match will see Scotland travel to face Switzerland on 16 November.

The team's home match against North Macedonia is set for 11 November.

The campaign will conclude with an away match against Switzerland on 16 November.

News

Golfer McIlroy Sinks Bunker Shot at Pebble Beach Pro-Am

At the AT&T Pebble Beach Pro-Am in California, Rory McIlroy achieved an eagle on the 14th hole at Spyglass Hill, capping off his opening round with a score of 68.

During the AT&T Pebble Beach Pro-Am in California, Rory McIlroy achieved an eagle on the 14th hole at Spyglass Hill, contributing to his first-round score of 68.

For further information, Rory McIlroy had a solid opening round, while Hisatsune took the lead.

Access to this content is restricted to users in the United Kingdom.

-

News8 hours ago

News8 hours agoAustralian Politics Faces Questions Over Gender Equality Amid Sussan Ley’s Appointment

-

News5 hours ago

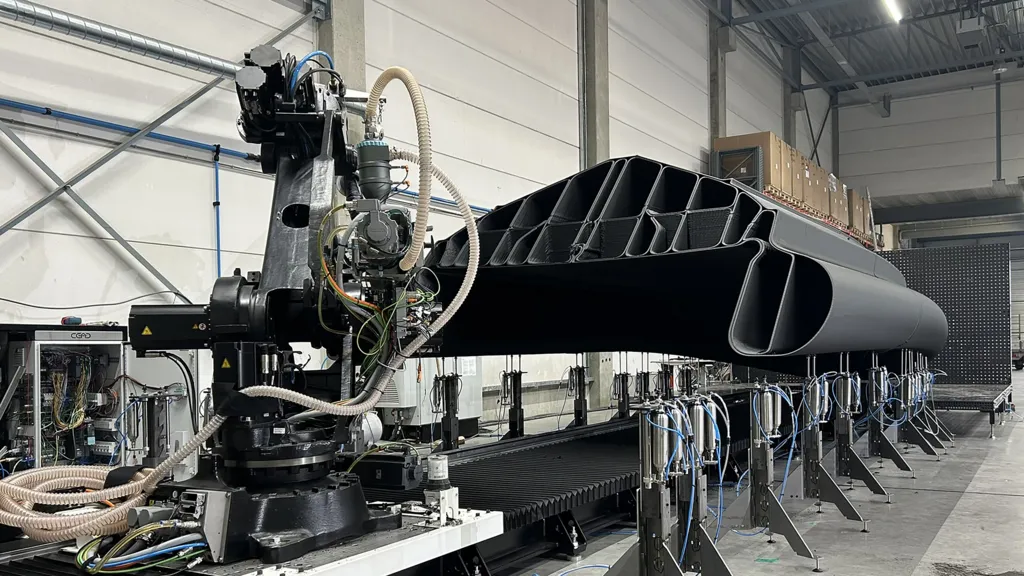

News5 hours agoFarage Says Reform to Replace Traditional Tory Party

-

News5 hours ago

News5 hours agoWrexham Pair Seek Win Against Former Team Ipswich

-

News11 hours ago

News11 hours agoLiberal Party Removes Australia’s First Female Leader

-

News8 hours ago

News8 hours agoUK Braces for Cold Snap with Snow and Ice Alerts Expected

-

News5 hours ago

News5 hours agoHusband’s alleged £600k theft for sex and antiques blamed on drug side effects

-

Business11 hours ago

Business11 hours agoBBC Reporter Exposed to Cyber Attack Due to Vulnerabilities in AI Coding Tool

-

News8 hours ago

News8 hours agoCanadian Town Unites in Mourning After Mass Shooting Leaves Community Reeling