News

Technology’s Impact on Traditional Baking and Food Production

The incorporation of robotic technology and automated systems in the food sector poses additional challenges.

The Thomas Tunnock factory, located just outside Glasgow, features a continuous flow of hot caramel that plays a crucial role in the production process.

This caramel, made on the second floor, travels down to the first floor via conveyor belts, filling the building with a warm, sweet aroma that is unmistakable.

However, working with caramel is a complex task that requires precision and teamwork; a team of 12 experienced workers must ensure the caramel reaches the correct consistency before applying it in five layers to create the signature Tunnock's wafer biscuit.

According to Stuart Louden, the company's engineering and transport manager and a fifth-generation member of the Tunnock family, the factory produces approximately 20 tonnes of caramel daily.

To achieve the perfect consistency, operators rely on a combination of visual inspection and tactile testing, often squeezing the caramel to assess its texture and quality.

Once the caramel is ready, it is transported to the floor below via a conveyor belt, where a dedicated team is responsible for applying it to the wafers.

As Mr Louden notes, spreading caramel onto wafers is an extremely challenging task due to its sticky nature, which demands a high level of skill and attention to detail.

While this particular aspect of the production process is labor-intensive, the majority of the factory's operations are automated, highlighting the company's efforts to balance traditional techniques with modern technology.

As a smaller player in the snack food industry, Tunnock's must adapt to stay competitive with larger companies like McVitie's and Fox's, and investing in advanced technology has been crucial in this endeavor.

Mr Louden emphasizes the importance of utilizing cutting-edge machines to maintain output and remain competitive, stating that as a "small fish in a big pond," the company must be strategic in its use of technology.

Although machines are used to spread caramel at night, the human workforce offers greater flexibility and requires less space, making it an essential component of the production process.

The combined efforts of humans and machines result in the production of approximately seven million wafer bars and 4.5 million tea cakes every week.

For Tunnock's, increasing output while preserving traditional methods is a delicate balancing act, one that requires careful consideration of the company's heritage and values.

The production of marshmallow, like caramel, is closely monitored by human supervisors to ensure the highest quality and consistency.

The company's commitment to traditional methods is also evident in its approach to packaging, where the wafer bar is wrapped rather than sealed, a decision that prioritizes quality over speed.

Mr Louden notes that the company's products often evoke nostalgic memories, with many customers recalling their childhood experiences with Tunnock's treats.

A new robotic arm developed for the cake industry aims to bridge the gap between traditional techniques and modern automation, offering a potential solution for companies like Tunnock's.

Unifiller, a technology brand of Coperion Group, has spent years developing the HIRO robot arm, designed to decorate cakes with a variety of toppings, including caramel.

The HIRO robot arm is capable of handling a range of toppings and can be used with various decorating tips, providing a high level of flexibility and precision.

According to Derek Lanoville, research and development manager at Coperion, the robot arm can work with any topping that can be squeezed through a pastry bag, making it a versatile tool for cake decoration.

Developing equipment for the food industry poses unique challenges, with hygiene being a top priority; equipment must be easy to disassemble and clean to prevent contamination.

Mr Lanoville emphasizes the importance of designing equipment that is easy to clean, stating that if it is not simple to disassemble, it may not be properly cleaned, compromising hygiene standards.

Unifiller collaborated with Swiss robotics firm Stäubli to develop the HIRO robot arm, which features a design that prioritizes ease of cleaning and maintenance.

Another challenge in the food industry is the inherent variability of products like cakes, which can differ in size and shape, posing a challenge for automation.

In most industries, components are uniform in size, but in baking, cakes can vary slightly in size and shape, requiring equipment that can accommodate these differences.

Mr Lanoville notes that the HIRO robot arm is designed to adapt to these variations, ensuring that it can decorate cakes accurately and efficiently, even when they are not perfectly uniform.

For Anomarel Ogen, head baker at The Bread Factory, human involvement is essential to the baking process, particularly when it comes to handling delicate dough.

The Bread Factory, which supplies products to the café chain Gail's, operates 24 hours a day, 365 days a year, and produces up to 40,000 loaves daily using around 16 tonnes of flour.

Although the bakery uses machines to mix and divide the dough, the process still requires a high level of human oversight and skill, particularly when working with sustainable, delicate flours.

The bakery's use of sustainable flours, which prioritize soil health, results in a more delicate dough that demands gentle handling and careful monitoring.

Machines are used to mix and divide the dough, but human workers play a crucial role in shaping the loaves, a task that requires years of experience and skill.

The bakery's commitment to sustainability is evident in its choice of flours, which are sourced from farms that prioritize soil health and environmentally friendly practices.

Mr Ogen highlights the importance of gentle handling when working with delicate dough, noting that the worker's touch and movement are critical in shaping the loaves.

The presence of human workers in the factory also allows for greater flexibility and adaptability, enabling the bakery to adjust its production process in response to changes in the recipe or dough.

As Mr Ogen notes, having staff on hand to monitor the production process and make adjustments as needed is essential for maintaining quality and consistency.

Introducing new technology to a production line requires a careful balance between automation and human oversight, according to Craig Le Clair, principal analyst at Forrester.

Mr Le Clair emphasizes the importance of developing a hybrid model that integrates automation with human involvement, preserving the unique qualities of handcrafted products while improving efficiency and consistency.

He notes that automation should be applied only to areas where it can bring significant benefits, such as speed, volume, and consistency, while leaving core value-added elements to human workers.

This approach allows companies to leverage the advantages of automation while preserving the essence of their products and the skills of their human workforce.

At Coperion, Mr Lanoville is already planning to develop the HIRO robot arm further, exploring new applications and refinements to enhance its performance and versatility in the cake decorating process.

The current priority is to refine the company's scanning, vision, and safety systems, allowing customers to work seamlessly without robotic interference.

In Glasgow, Mr. Louden is considering an upgrade to his production line, but the project's feasibility depends on the current financial climate, which has been affected by fluctuating cocoa prices over the past two years.

With a potential investment of £2.5 million in equipment, the company is adopting a cautious approach, delaying the decision due to the unfavorable market conditions of the past two years, and seeking to avoid any financial risks that could have a negative impact.

News

GB men’s curling team suffers upset defeat to Italy

At the 2026 Winter Olympics, Great Britain’s men’s curling team mounted a comeback against Italy following a disappointing beginning, ultimately falling short in their inaugural match.

Despite a valiant comeback, Team GB ultimately fell short as Italy held their composure to secure the win in the final end.

A dismal start to the match proved costly for Team GB's men, as they suffered their first defeat of the Winter Olympics at the hands of host nation Italy, despite a spirited fightback in the packed Cortina Curling Stadium.

Following victories in their first two matches, including a win over the Swedish rink that beat them in the gold-medal match four years ago, Team GB entered their second high-profile encounter in as many days in a confident position.

However, a disastrous opening end, in which Italy stole four points, left Team GB trailing and facing an uphill battle in front of a boisterous home crowd.

The British team, currently ranked number one in the world, gradually regained their footing and managed to level the score by the ninth end.

Ultimately, Italy maintained their composure in the final end to emerge victorious, winning 9-7 and adding Team GB to their list of scalps, which already included the Swedes.

"We had to dig deep and play some solid curling, but unfortunately, it wasn't enough to get us over the line," Team GB lead Hammy McMillan said in an interview with BBC Sport.

With seven wins from nine round-robin matches guaranteeing a spot in the semi-finals, Team GB remains in a strong position, although fewer wins may still be sufficient to advance.

The women's team is set to take to the ice next, facing South Korea in their second match at 13:05 GMT, while the men will return to action on Saturday against the Czech Republic at the same time.

Team GB is at the forefront of curling's technological advancements.

Embracing what sets you apart can be a powerful asset, according to some athletes.

A daily guide to the Winter Olympics is available for those looking to stay up-to-date with the action.

The looks of shock on the faces of Team GB's curlers told the story of a disastrous opening end.

With a stone in play, Mouat attempted a risky shot in an effort to claim two points, but it backfired, resulting in none of Team GB's stones in the house and four Italian stones in position.

However, the Scottish quartet, ranked number one in the world, quickly regained their composure and got back to their game.

The teams exchanged singles before a impressive final throw by Mouat, aided by a measurement to determine which stone was closest to the button, allowed Team GB to claim two points and narrow the gap to 5-3.

Another excellent team effort, which included a well-judged throw by Mouat, a solid sweep by Hammy McMillan and Bobby Lammie, and Grant Hardie's strategic expertise, forced Italy to concede a point in the fourth end, reducing the deficit to a single point at the break.

Italy blanked the sixth end and added two points in the seventh to rebuild their lead, but Team GB fought back with two points of their own, remarkably levelling the score with one end remaining after a steal.

The match came down to the final end, but Italy held their nerve to secure the win, prompting a deafening roar from the crowd.

"It's an incredible experience, and we need to get used to it," McMillan added, describing the electric atmosphere as "surreal" and "cool," more akin to a football match than a typical curling crowd.

News

Scotland Kicks Off Nations League Against Slovenia

Uefa has released the schedule for the Nations League, with Scotland set to begin their campaign on 26 September with an away match against Slovenia.

Uefa has released the schedule for the Nations League, with Scotland's campaign set to begin on 26 September with an away match against Slovenia.

The team's six group stage games will be played within a three-month period, culminating in a match against Switzerland on 16 November.

The fixture list was announced following Thursday's draw, which placed Scotland in a group with Switzerland, Slovenia, and North Macedonia.

Having been relegated from League A after a play-off loss to Greece last year, Scotland will compete in the second tier of the Nations League this year.

In response to the draw, head coach Steve Clarke noted that the teams in the group appear to be evenly matched.

Clarke reflected on the team's past experience in the competition, stating that it has been beneficial for Scotland.

He emphasized the importance of the Nations League, citing its role in helping the team qualify for Euro 2020, and anticipated a challenging set of matches.

A key matchup in the Nations League will see Scotland face off against Switzerland.

The group stage will determine the teams' fates, with the winner earning promotion, the runner-up entering a play-off, the third-placed team facing a relegation play-off, and the fourth-placed team being relegated directly.

The upcoming group games will mark a reunion for Scotland and Switzerland, who previously drew 1-1 in Cologne at Euro 2024.

Scotland's last encounter with Slovenia was during the 2018 World Cup qualification campaign, when they won 1-0 at home and drew 2-2 away.

The team has not played North Macedonia since the 2014 World Cup qualifiers, when they drew 1-1 at home and won 2-1 away, with goals from Ikechi Anya and Shaun Maloney.

The schedule for Scotland's Nations League campaign begins on 26 September with a match against Slovenia.

The team will then host Switzerland on 29 September, followed by a trip to face North Macedonia on 3 October.

Scotland will then play Slovenia at home on 6 October, before hosting North Macedonia on 11 November.

The final group stage match will see Scotland travel to face Switzerland on 16 November.

The team's home match against North Macedonia is set for 11 November.

The campaign will conclude with an away match against Switzerland on 16 November.

News

Golfer McIlroy Sinks Bunker Shot at Pebble Beach Pro-Am

At the AT&T Pebble Beach Pro-Am in California, Rory McIlroy achieved an eagle on the 14th hole at Spyglass Hill, capping off his opening round with a score of 68.

During the AT&T Pebble Beach Pro-Am in California, Rory McIlroy achieved an eagle on the 14th hole at Spyglass Hill, contributing to his first-round score of 68.

For further information, Rory McIlroy had a solid opening round, while Hisatsune took the lead.

Access to this content is restricted to users in the United Kingdom.

-

News8 hours ago

News8 hours agoAustralian Politics Faces Questions Over Gender Equality Amid Sussan Ley’s Appointment

-

News5 hours ago

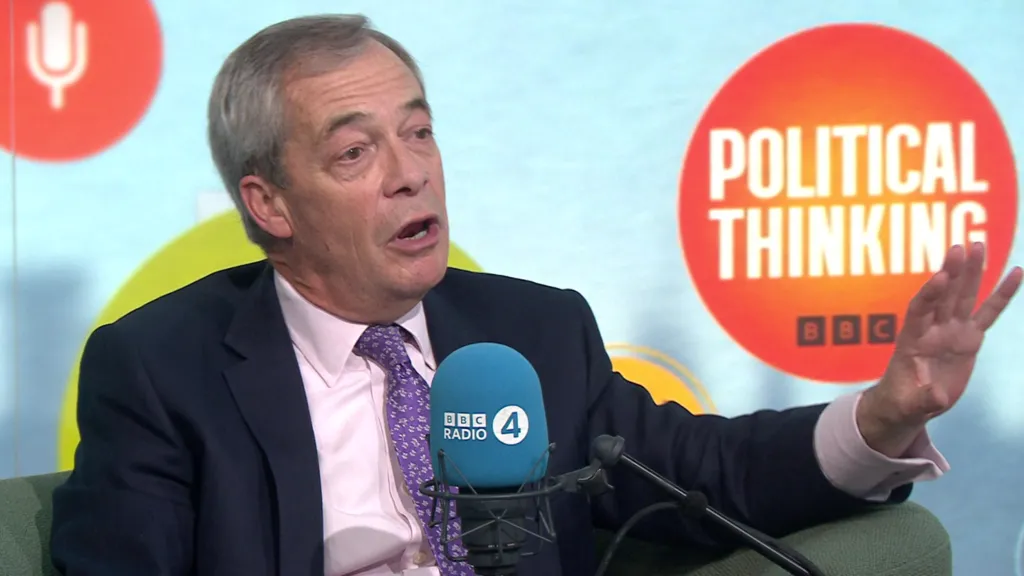

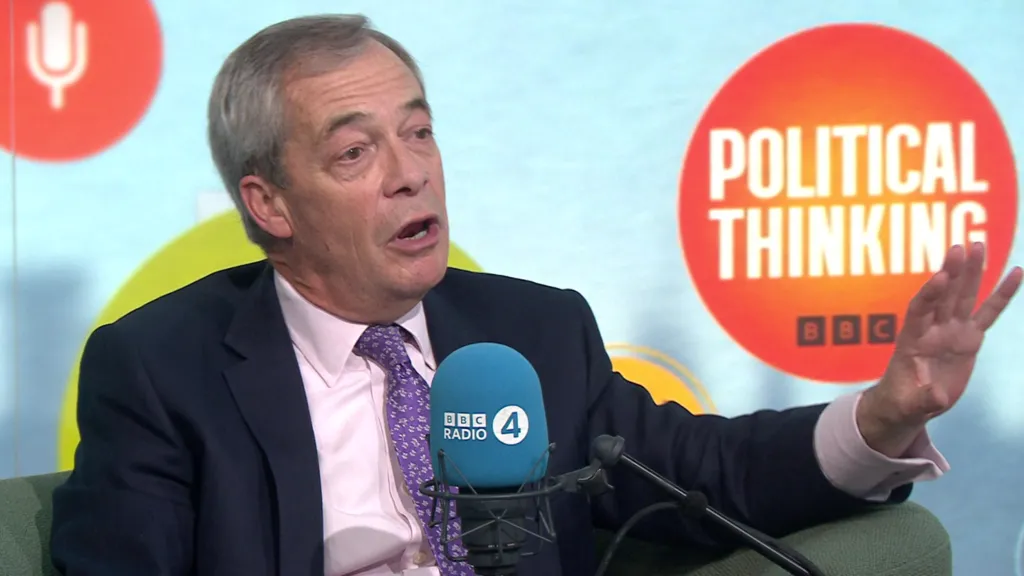

News5 hours agoFarage Says Reform to Replace Traditional Tory Party

-

News5 hours ago

News5 hours agoWrexham Pair Seek Win Against Former Team Ipswich

-

News11 hours ago

News11 hours agoLiberal Party Removes Australia’s First Female Leader

-

News9 hours ago

News9 hours agoUK Braces for Cold Snap with Snow and Ice Alerts Expected

-

News5 hours ago

News5 hours agoHusband’s alleged £600k theft for sex and antiques blamed on drug side effects

-

News2 days ago

News2 days agoSunbed ads spreading harmful misinformation to young people

-

Business11 hours ago

Business11 hours agoBBC Reporter Exposed to Cyber Attack Due to Vulnerabilities in AI Coding Tool